Currently, the use of natural fibers as reinforcements in composites offers several advantages, such as a decline in materials derived from non-renewable resources and a reduction in the effects on the environment. These substances have been effectively utilized in the fields of tissue engineering, wound care, drug delivery, and nanotechnology as hydrogels, scaffolding, matrices, and implantation. In terms of implants and other medical technology, biomaterials significantly contribute to the revolutionizing of human existence. Fundamentally, these materials must be extremely biocompatible and unaffected by physiological conditions in humans. Nevertheless, biodegradability is also a drawback of natural materials, as they cannot be as long-lasting as conventional artificial substances and are more prone to wear and tear because of their close contact with human tissue. Because the efficacy of a medical device depends on its suitability and capacity to perform the desired operation, selecting the appropriate material is crucial when developing a medical device. Therefore, by emphasizing modern advances in natural materials and applications, this study aims to emphasize both the fundamental characteristics of natural fibers and recent developments in the biomedical field. Finally, the impact of these implant materials on improving human life is also discussed.

Avoid common mistakes on your manuscript.

The preservation of the environment along with energy is one of the major concerns confronting today’s generation. Currently, new methods are required to protect the environment and yield sustainable items [1]. The modern world is largely dependent on materials derived from crude oil, such as petroleum products, which are then transformed into a variety of uses, including energy sources, everyday items, household items, cars, aerospace, commercial, and a wide range of other items. However, the processing of these materials pollutes the environment heavily, and more crucially, it takes many years for these materials to decay [2]. Today, composites play a significant role in the creation of numerous components to substitute for these constraints. Composites are hybrid substances that combine the excellent physical and mechanical properties of fibers with a polymer resin for reinforcement. Composites of polymers with lightweight properties, excellent stiffness, and durability have excellent corrosion resistance. These composites are cost-effective because they use affordable raw materials and require minimal maintenance [3, 4].

Polymer utilization has increased dramatically because of the desire of people to embrace better living circumstances. The polymer matrix is mixed with fibers, which may be either artificial or synthetic, to increase strength and consumption [5]. Synthetic fibers have attracted special attention because of their superior characteristics compared to natural fibers. The longer lifespans of artificial fibers provide significant benefits for high-end industries [6, 7]. The aforementioned fibers can be formed with unique properties desired for specific usage and outstanding durability. Carbon fibers, for instance, offer high strength, low to no absorption of moisture, excellent thermal resistance, and excellent electrical and thermal conductivities. The as-prepared composite materials can be used in advanced applications such as wind and energy storage on a large scale because of their characteristics.

In contrast, the drawbacks of artificial fibers include their buildup in waste and/or the environment, their high cost, and the fact that they are made from limited supplies, namely fossil fuels [8]. Additionally, hazardous gases that cause severe diseases, including cancer, are released throughout the manufacture of composites, and they can be abrasive to the machinery used for processing [9]. These restrictions encourage the use of natural fibers, which are essential for modern scientific studies because they are renewable, freely accessible, and require less processing. The recyclability of natural fibers is also of great importance [2].

A wide range of materials, known as biocomposites, is being used more often in a variety of sectors. The ability of biocomposites to be tailored to various industries is one of their primary advantages. Most natural fibers can generally be utilized to create various bio-composite items. The primary factor to consider is the makeup of these fibers because they affect some essential characteristics of biocomposites. To create any bio-composite substance, understanding the chemical makeup of natural fibers and their adhesion surface qualities is crucial. [10].

To solve challenges with the replacement and reconstruction of missing, injured, or dead (or “non-functional”) tissues, bioengineering involves the use of ideas and techniques from an engineering perspective. Any substance employed for this function can be categorized as a biomaterial. Biomaterials have had a significant impact on how people live because of implants and other technological advances in medicine. High biocompatibility and resistance to changes in human physiological conditions are the main characteristics of these materials [11]. This engineering and material science institution collaborates with the field of biomedical engineering, a multidisciplinary subject that uses principles related to medical biology and design standards to improve human health. The physiology and anatomy of people create biomaterial concepts that, when created and incorporated into the human body, to promote tissue repair or substitution or as a full tissue substitution, would perform their desired functions without endangering their instantaneous tissue surroundings or the entire body system [12].

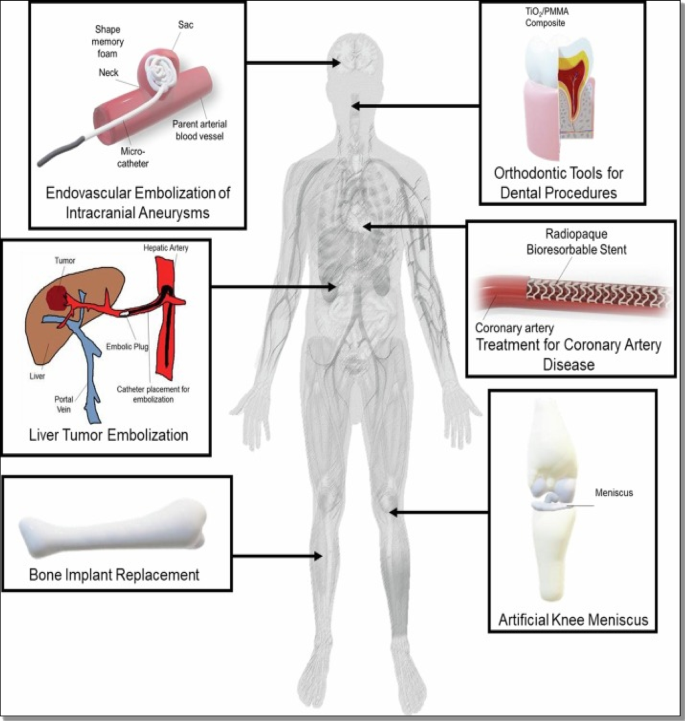

Typical types of medical equipment include prosthetic knee and hip joints, implant dentistry, internal and exterior fracture fixators, replacement heart valves, and the repair of skin templates. The ability of bio composite substances to be specifically tailored to the needs of various uses is a key advantage. Owing to the intimate interconnection of the components, relative stability, and difficulty in separating and recycling, these composite constructions present a challenge for ordinary elimination after a lifespan [13, 14].

Because of their distinct biocompatible qualities, both stainless steel and titanium have been employed as bone plates in bone reconstruction for a long time. Nevertheless, using these materials for bone restoration necessitates multiple additional surgical procedures to eliminate the risk, which may put individuals through unneeded pain or discomfort [15]. As the bone and plates vary in stiffness, the bones can refract once the plates are removed. It also includes a comparison of the characteristics of bone and cartilage with those of various other substances. Consequently, fewer rigid materials should be used to manufacture plates for bone fixation. Therefore, it is essential to understand and research diverse fiber types for their properties and applications in the creation of composites. In addition, the durability of these composites can be improved by adding nanoparticles or changing their chemistry [16].

This paper offers a thorough, analytical examination of the development of a few natural fiber-based membranes and materials that are now being used to create reliable, portable, and usable systems, as well as an analysis of their drawbacks, difficulties, and prospects for the future. In addition, it summarizes the knowledge of fiber-reinforced composites, including how they might be used in the medical field. The author offers an overview of the numerous biomedical functions that these materials have so far performed effectively in fields including dentistry, tissue repair, bone regeneration, wound healing, total hip replacement, and total hip replacement. The author concludes by considering potential future directions for the development and enhancement of novel biomaterials with a greater variety of superior biological applications.

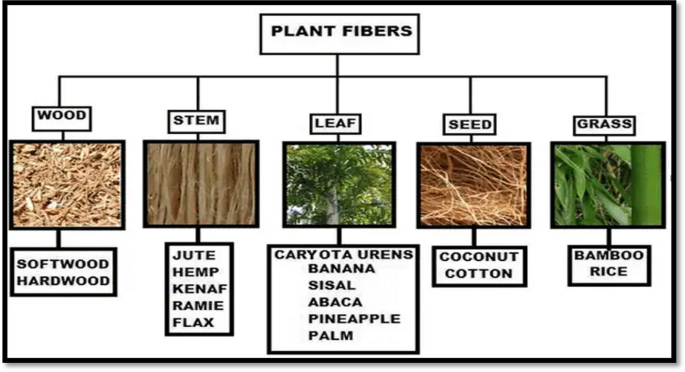

One of the most extensively studied issues in recent years is the consumption of natural fibers instead of manufactured fibers. This is because of their natural assets, which include being more biodegradable, renewable, and widely available than synthetic fibers, as well as their pleasant processing (lower tool wear and less skin discomfort) and effective acoustic and thermal insulation qualities. Natural fibers also have superior specific strength and stiffness compared to glass fibers because of their low specific weights. However, drawbacks such as inconsistent quality, moisture absorption, poor durability, weak impact resistance, and restricted production temperatures prevent the use of more natural fibers [17]. Natural fibers are used directly in one-dimensional items such as lines and cables. Additionally, natural fibers have been used in ancient times for stringing ships, suspending bridges over water, and other purposes [18]. Natural fibers can be made from a variety of sources, including wool, silk, and chicken feather filaments, as well as sisal, hemp, kenaf, jute, ramie, oil palm, pineapple, and banana [19]. The categorization of plant fibers is shown in Fig. 1, which provides an overview of the variety of wood and non-wood fibers [20].

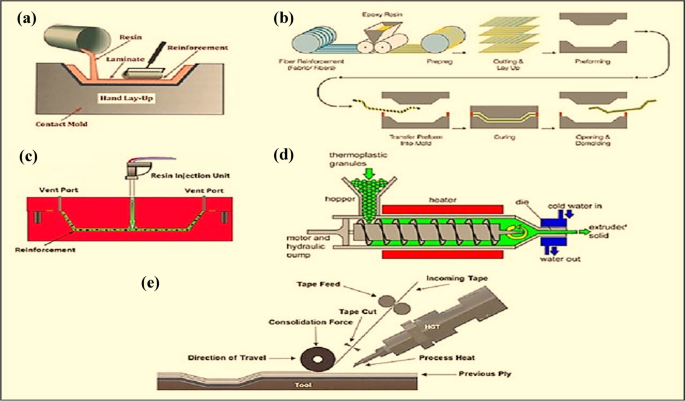

Table 1 shows that the chemical makeup depends on the fiber supplier and changes within various regions. Their chemical composition, crystal growth, microfibrillar angle, defects, and physical properties affect how they operate [21, 22]. The hand layup method, compression molding, resin transfer shaping, extrusion procedures, and automated fiber insertion are some of the manufacturing processes used for NFRC, as illustrated in Fig. 2 [23].

Reduced densities give natural fibers certain strength and stiffness features that are similar to those of artificial fibers, as shown in Table 2. Natural fibers have lower mechanical properties than synthetic fibers. The potential to create composite components that are considerably lighter than those that are currently achievable with sophisticated fibers is one of the most attractive features of natural fibers and, consequently, their composites [25]. The tensile, impact, flexural, and flexural properties of natural fiber composites are crucial to their performance. The most frequently researched mechanical attributes of composites are their tensile durability. The geometrical features of the fiber, such as thickness or diameter, have a considerable impact on the tensile strength of a single fiber. The flexural characteristics of the composite corresponded to the dimensions of the samples used for the laboratory test; in this case, the surface to which the load was applied was critical [26]. When selecting a precise natural fiber for a certain application, fiber strength can be a key consideration. It is necessary to consider the fiber size, defects, strength, uniformity, crystallization, and content [27].

Implant material degradation can be caused by various factors, including inadequate toughness, durability against wear, strength to yield, and biocompatibility [44]. Therefore, choosing a material for a femoral prosthetic is challenging because the implant is subjected to a variety of biological and mechanical challenges after being inserted into hostile physiological surroundings of the human body [45, 46]. The implantation material must be corrosion- and wear-resistant, and biodegradable [45]. Furthermore, Young’s modulus of the prosthesis material directly affects its resilience to stress and endurance [48, 49]. Typical alloys (Ti alloy, Cr-Co alloy, and St alloy) used in femoral prostheses have Young’s modulus constants that are ten times greater than those of cortical bone. Therefore, stress sheltering leads to THR failure [50]. In recent years, there has been increasing demand for this industry to employ innovative and environmentally friendly materials. Collagen, a soft (with low elastic strength) polymeric material, is joined with the ceramic component hydroxyapatite to form a natural composite known as bone. Although ceramics are well known for their brittle nature, hydroxyapatite offers the strength required for sustaining the human body [51]. The mechanical characteristics of the bones are displayed in Table 3. Orthotics and prosthetics utilizing composite materials have recently received considerable interest. As a result, a combination of fiber-reinforced polymers can be used to create contemporary upper- and lower-limb prostheses and can be efficiently used in orthopedic surgery [49, 52]. Custom-made composites with a polymer matrix may substitute traditional titanium- and stainless steel-based implants and approximate the characteristics of bone [53]. Composites made from natural fibers have been mentioned as possible components of prostheses [54]. Hamad et al., for illustration, investigated the mechanical characteristics of composites for prosthesis sockets that were developed utilizing vacuum bagging technology and strengthened with natural fibers as if sisal were coupled with carbon fiber, glass, and perlon and bound inside a PMMA resin [55, 56].

The substances that medical professionals employ to treat dental issues and repair decaying teeth have undergone significant research and advancement in the past few decades. The focus of traditional dental research has now switched from repair to renewal of dental tissues, whereas the customary idea was to remedy the deficiency. As a result, a variety of “bioactive” materials has been developed, suggesting that they can quicken or encourage biological reactions to replace missing tooth tissues [57]. Metals have more elastic characteristics than bone; hence, biocomposites consisting of ceramic and polymer have been researched as suitable metal implantation substitutes. Currently, amalgamated materials such as gold, aluminum oxide, zirconia, and other traditional restoration substances, have been replaced with synthetic resins that simulate biological tissues [58]. The main drawbacks, which require more analysis, are their endurance, polymerization shrinking, thermal expansion imbalance, and cytotoxicity [59]. PMMA was given an improvement in diffusivity by the addition of ceramic microwires made of alumina oxide [60]. Due to their biological compatibility and capacity for cellular integration, polymer-ceramic hybrids such as hydroxyapatite-strengthened polyethylene are employed as replacements for bones and implants in dentistry [61]. Recent research has looked at biocomposites made with natural fiber that could substitute for the current materials. In recognition of sisal’s great compatibility with human cells, Sosiati et al. developed sisal/PMMA biomedical composites to show that the finest attributes for dentistry and prosthetic usage came from a load of 30% of the fibers [62].

Tissue repair (TR) is the process of restoring the shape and functionality of tissue that has been injured by surgical procedures, mechanical trauma, or chemical contact [63]. Bioactive elements are crucial to tissue engineering because they maintain structural integrity, control cellular activity, and create an optimal environment for the regeneration of tissue. Utilizing synthetic scaffolds and an assortment of biomaterials, tissue engineering with biocomposites repairs and restores tissues that have been damaged [64]. Collagen is a significant natural bioactive substance that has been extensively employed. It naturally occurs in the skin and is considered the pinnacle of excellence in tissue regeneration [65]. This review [66] illustrates the use of several biomaterials, including bioceramics, bioactive glasses, artificial and natural polymers, and their associated composites, in the construction of scaffolds (a key component of tissue bioengineering). Due to their decreased immunogenicity compared to their glass or artificial equivalents, cellulosic and lignin, fabrics are useful for a variety of biological uses, including the delivery of drugs, tissue engineering, and restoration [67]. In recent years, the industry has increasingly used bioplastics, including polycaprolactone, lactic acid, and polyglycolide, and their co-polymers, as bio-restorable polymers for tissue engineering applications. Because it can be biodegraded by the fungus and bacteria found in human systems [68], bioplastics are injected into the systems of people for biomedical reasons. This frequently demands that the bioplastics be biodegradable and non-toxic so that their use does not necessitate a further procedure to be eliminated from the human body and does not harm the users [69].

Trauma, malignancy, genetic bone deformities, diseases, and bone-related illnesses, including osteoporosis, can all result in defects in the bones [70]. Natural bones are an intricately arranged system of biological and inorganic elements with little ability to repair and replace damaged tissues. Tissue bioengineering has been offered as an intriguing way to enhance bone restoration [71]. One of the main objectives of tissue engineering is to substitute the injured bone with a scaffold to restore efficiency in the affected area [72]. Over the past decades, numerous biomaterials made of organic and artificial polymers, as well as ceramics, have been investigated for use in the engineering of bone tissue. Biocomposites made of hydroxyapatite combined with various resins have been researched in the context of bone restoration [73, 74]. Additionally, scaffolds must be biodegradable and have a controlled disintegration rate that corresponds to the development of cells in the tissue to substitute tissue or repair damaged portions. This will enable cell adhesion, proliferation, and ultimately the replacement of the area of damage by the development of tissue. Previously, the mechanical qualities of the scaffold, especially stiffness, should have resembled those of the tissue being replaced [75]. Hybrid scaffolds composed of PGA and tricalcium phosphate (TCP) chemicals mimic the native bone elements, making their effective incorporation into adjacent tissue visible [76]. Then, by combining poly (e-caprolactone) and hyaluronic acid esters, reproducible scaffolding structures were generated [77, 78]. Utilizing biocomposites as scaffolds made of diverse natural fibers is the current trend. For the production of implantable bone tissue scaffolds, natural fibers like hemp, kenaf, bamboo, bananas, sisal, flour, sugar cane, palm oil, cotton, and coconut are gaining popularity. Waste from agriculture is employed as a basis for fibers in altered biopolymers to create ecologically acceptable, more cost-effective, and substantially strengthened scaffolds. Examples of these wastes include almond shells, sugar remains, and walnut trash [79].

Skin injuries are a particular kind of damage that changes the tissue’s form and causes atypical behaviors. Both acute and chronic wounds to the skin involve a very convoluted process for wound repair, making current therapies very difficult to use in clinical settings. The application of appropriate topical bandages with remarkable capabilities to speed up the healing process of wounds is one of the primary medical approaches to healing persistent wounds [80, 81]. The ideal dressing for a wound should be safe, non-allergenic, economical, compatible without repulsion or inflammatory processes, provide bacterial prevention that permits fluid transfers, provide moisture, provide a desirable recovery environment, and speed up the healing process [82, 83]. The use of biocomposites increases the likelihood of discovering an assortment of constituents that can meet the design specifications of wound dressings since deterioration must correspond to the skin renewal rate to preserve moist surroundings. Both the biomaterial content and the manufacturing technology are crucial for obtaining such appropriate dressing substances. Therefore, biomaterials including the proteins collagen, chitosan, keratin, and artificial polymers like poly(lactic acids), ethylene oxide, polycaprolactone, and poly(lactic-co-glycolic acids), among others, may be ideal for use as dressings for skin rejuvenation [84, 85]. Natural substances are now often employed in wound treatment procedures because of their therapeutic benefits, economic viability, and lack of side effects. However, these medications have low absorption and are not over-the-counter stable, which causes a sluggish recovery [86, 87]. To hasten the recovery of wounds, various contemporary surgical dressings are made of nanotechnology fibers that can be packed with organic materials like phenolic substances or extracts from plants and studied for their dissolution behavior and antimicrobial, antioxidant, and anti-inflammatory properties. The active compounds that the nanofibers may release include artificial or natural antibiotics, as well as various chemicals with inherent bacteriostatic and/or bactericidal properties that can speed up the recovery process [88, 89].

Studies have been centered on creating innovative methods for delivering pharmaceuticals with greater efficiency and security into the human body [90]. Using biologically compatible and biodegradable carriers for drugs can help prevent or reduce the adverse effects that could lead to delivering medications to cells with higher effectiveness and performance during health restoration. These are metals, ceramics, or polymer biomaterials. Naturally, produced degradable polymers that are suitable for drug delivery systems include enzymes (collagen, albumin, etc.) and carbohydrates (starch, chitosan, etc.) [91]. Today, bioplastics that degrade over time are used in medical fields such as implanting therapeutic devices and regulating systems for drug delivery. While preserving the usefulness and integrity of the devices, the materials utilized in these kinds of applications should have excellent resistance to a variety of chemicals and sterilizing techniques [92, 93].

Recently, nanocarriers have been intensively researched and used in medical and therapeutic fields as drug delivery mechanisms. Several methods are used to create nanofibers from natural plastics such as chitosan, cellulose, and silk, including electrospinning or self-made approaches [94]. Research in the field of public health is increasingly focusing on the creation of efficient medication delivery methods that enable biologically active compounds to get to their point of action while evading non-target organs, cells, or tissues [95, 96]. Several benefits of drug-embedded nanocomposites, such as chitosan nanocomposite, include enhanced pharmacokinetics and the ability to transport medications to the desired place or tumor [97].

For focused drug delivery, these nanofibers’ large surface area-to-volume ratio enables improved medication-loading abilities and regulated release patterns. Orasugh et al. developed a jute cellulose nano-fibrils/hydroxypropyl methyl hybrid as a novel material with a possible application in delivery systems [98]. Enhanced mechanical durability, adaptability, thermal resistance, water absorption ability, regulated medication release, and superior skin adhesive qualities are all provided by nanotechnology. Additionally, adding nanoparticles, including magnetized, gold, or silver ones, to natural plant fiber offers significant promise for giving the finished nanocomposites magnetized, antimicrobial, or antibacterial capabilities. These hybrid substances exhibit enhanced wound healing aptitudes, antimicrobial impacts, and diagnostic features [68, 99]. Due to their decreased immunology compared to their glass or artificial equivalents, cellulosic or lignin reinforcements are appropriate for a variety of biological uses, including drug delivery [72, 82]. Since the overall drug release proportion decreases when the CNF level in the nanocomposite layer increases, cellulose nano-fibrils (CNF), which originate from unprocessed jute filaments, are a great option for cutaneous drug delivery systems. They have a large surface area, attractive rheological characteristics, ensure water absorption, and are harmless. The application of sisal fiber in the fields of tissue engineering, beauty products, and medicine delivery is possible [100, 101].

It is clear from the review if NFRPC utilization for industrial healthcare fields is appropriate given that these materials are biocompatible, have mechanical strengths equivalent to artificial fibers, and have a smaller environmental footprint. However, it is quite challenging to improve and manage the general features of NFRPCs. Further study is also needed from the scientific community to support and encourage the use of innovative NFs in the development of NFRPCs. Concerning reliability, longevity, and most crucially, the biocompatibility of NFRPCs, there is an awareness gap. Durability is a concern if the composites are utilized in environments where they are not shielded from the elements, biological threats, etc. The main technical issues that need to be resolved for the use of NFRPCs are polymer and fiber deterioration, a high level of moisture, combustibility, fluctuation in natural fiber structure, and inadequate interaction between fibers and polymers. NFRPCS needs to be used more frequently to comprehend how to enhance its qualities. It might infer that NFRPC advancement is quickening and that it is anticipated as a potential sustainable substance for fresh uses. Future research is necessary to solve the difficulties in creating NFRPC for commercial and medicinal uses, though.

Despite these drawbacks, NFRPC usage has been growing encouragingly, especially in the field of healthcare. Future NFRPC target areas include the creation of novel materials, fiber-matrix interfacial properties, fiber uniformity, and interlayer bonding. The hybridization of composites generated from different natural fibers also aids in the development of various medical systems. Further investigation is needed to address the difficulties of NFRPCs, including different constraints that all affect the service life of NFRPCs, to attain long-term viability for bioengineering purposes.

This review summarizes modern bio-composite material usage in biomedical engineering, with an emphasis on hip substitution, implant dentistry, regeneration of bones, wound healing, medicine delivery, and tissue reconstruction. The review demonstrated that many forms of biomaterials, including bio ceramics, active glasses, artificial and natural polymers, and their resulting composites, have great potential for use in a variety of biomedical engineering applications. Tissue engineering is dependent on scaffolding biological materials, which are difficult to work with due to their complicated nature. Injuries to the skin continue to be a problem for the advancement of dressing materials, as wound dressings must be biodegradable, contain a substantial amount of water, and facilitate the exchange of gases. Disintegrating cellulose nano fibrils have altered the regulation of medication design and biomaterial suitability for implants and tissues. Since the composition and strength of the hip joint replacement assess how the load passes utilizing the stem, multiple issues associated with hip joint replacement have been identified, such as damaging tissue response, allergic reactions, wear, and resistance to corrosion. To solve this issue, new biomaterials must be developed. Finally, natural fiber–strengthened composite materials with remarkable resilience and biocompatibility are becoming increasingly popular in current orthopedic treatments. Apart from that, it represents significant technological progress in the fields of dental cosmetics and lower-limb prosthetics. The sustainability and prospective utilization of reinforced natural fiber in the future with property reinforcement are, in essence, their benefits. Therefore, more investigation and study into reinforced biomaterials is required to expand the uses for reinforced natural fiber. Future research could concentrate on the qualities of natural fiber, the compatibility of biomaterials with diverse natural strengthening substances, and the prospective use of various bio-resources as reinforcement materials.

It was formed through the investigation as are issue to a data-sharing order and reachable on an open basis that does not clash datasets with DOIs.

The author thanks all the educators and employees at of misan university/collage of engineering.